Investigation of the visual appearance of different skirt styles and materials during the fitting simulation with Lectra Modaris

DOI:

https://doi.org/10.25367/cdatp.2021.2.p141-150Abstract

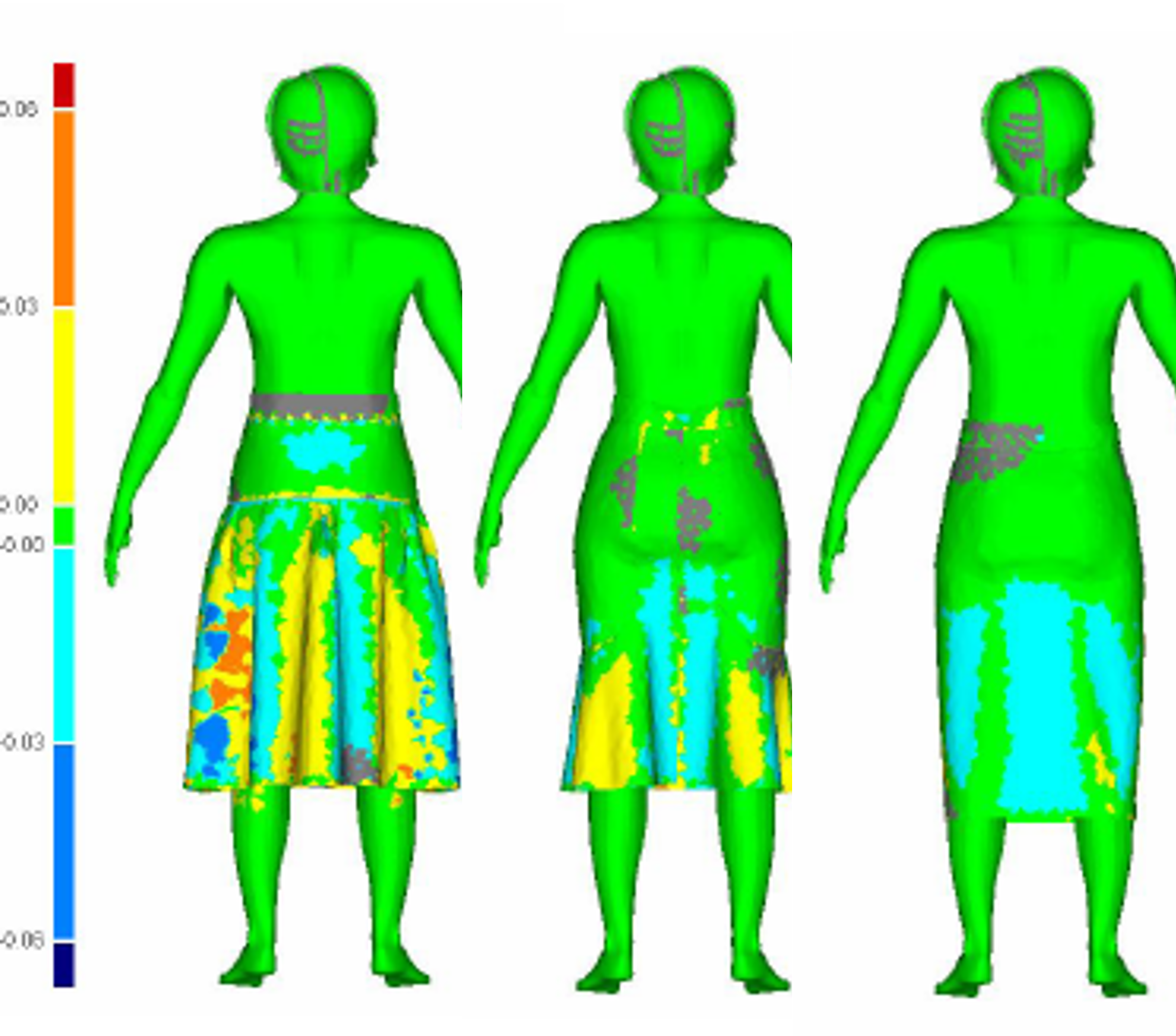

This paper examines the influence of different fabric types and material properties on the visual appearance of three types of skirt styles using numerical simulation. The purpose of the simulation is to present and analyze the appearance of virtual garments, create the best-fitting pattern pieces, and choose the appropriate fabric type based on the multiple clothing styles to achieve the intended design. The results show that when the type of fabric changes without changing the clothing style and on the other hand the style changes without changing the type of material, the appearance of the garment changes and the effect can be clearly seen with the 3d comparison result. These changes should be taken into account when choosing the right fabric for different styles.

References

Clothing and Appearance | Encyclopedia.com. Available online: https://www.encyclopedia.com/history/news-wires-white-papers-and-books/clothing-and-appearance (accessed on June 12, 2020).

Lage, A. and Ancutiene, K. 2017. Virtual try-on technologies in the clothing industry. Part 1: investigation of distance ease between body and garment. The Journal of The Textile Institute 108, 10, 1787-1793. DOI: https://doi.org/10.1080/00405000.2017.1286701.

Sayem, A. S. M.; Kennon, R.; Clarke, N. 2010. 3D CAD systems for the clothing industry. International Journal of Fashion Design, Technology and Education 3, 45-53. DOI: https://doi.org/10.1080/17543261003689888.

Liu, Y.-J.; Zhang, D.-L.; Yuen, M. M.-F. 2010. A survey on CAD methods in 3D garment design. Computers in Industry 61, 6, 576-593. DOI: https://doi.org/10.1016/j.compind.2010.03.007.

Liu, K. X; Zeng, X. Y.; Bruniaux, P.; Wang, J. P.; Kamalha, E.; Tao, X. Y. 2017. Fit evaluation of virtual garment try-on by learning from digital pressure data. Knowledge-Based Systems 133, 174-182. DOI: https://doi.org/10.1016/j.knosys.2017.07.007.

Büyükaslan, E.; Jevsnik, S.; Kalaoglu, F. 2015. Virtual fitting of a skirt on a parametric and a scanned body model. Marmara Journal of Pure and Applied Sciences 27, 23-26. DOI: https://doi.org/10.7240/mufbed.52347.

Assyst - Products - 3D Vidya. Available online: https://www.assyst.de/en/products/3d-vidya/index.html (accessed on September 20, 2021).

[CLO/3D] Introduction to CLO – A 3D CAD Tool for the Apparel Business – How to Install | STYLY. Available online: https://styly.cc/tips/clo_awai_install/ (accessed on August 16, 2020).

Hong, Y.; Bruniaux, P.; Zhang, J. J.; Liu, K. X.; Dong, M.; Chen, Y. 2018. Application of 3D-TO-2D garment design for a typical morphology: a design case for physically disabled people with scoliosis. Industria Textila 69, 1, 59-64. DOI: https://doi.org/10.35530/IT.069.01.1377.

VStitcher 3D Apparel Design Software. Available online: https://browzwear.com/products/v-stitcher/ (accessed on August 18, 2020).

Jevsnik, S.; Stjepanovic, Z.; Rudolf, A. 2017. 3D virtual prototyping of garments: approaches, eevelopments and challenges. Journal of Fiber Bioengineering and Informatics 10, 51-63. DOI: https://doi.org/10.3993/jfbim00253.

Ögülmüş, E.; Üreyen, M. E.; Arslan, C. 2015. Comparison of real garment design and 3d virtual prototyping. Proc. of 15th AUTEX World Textile Conference 2015, June 10-12, 2015, Bucharest, Romania.

Bias, R.G.; Larson, K.; Huang, S.-C.; Aumer-Ryan, P. R.; Montesclaros, C. 2010. An exploratory study of visual and psychological correlates of preference for onscreen subpixel-rendered text. Journal of the American Society for Information Science and Technology 61, 4, 745-757. DOI: https://doi.org/10.1002/asi.21273.

Kyosev, Y. Material description in the simulative 3D textile products development: data structure, open data exchange formats and system for automatic analysis of experimental series, Textile Research Journal, in Printing (11.2021), Online First, https://doi.org/10.1177/00405175211061192.

Cieśla, K.; Frydrych, I.; Krzywinski, S.; Kyosev, Y. 2020. Design workflow for virtual design of clothing for pregnant women. Communications in Development and Assembling of Textile Products 1, 2, 148-159. DOI: https://doi.org/10.25367/cdatp.2020.1.p148-159.

Salopek Cubric, I.; Cubric, G.; Potocic Matkovic, V. M.; Pavko Cuden, A. 2021. The comfort of knitted fabrics: interaction of sportswear and athlete’s body. Communications in Development and Assembling of Textile Products 2, 1, 70-79. DOI: https://doi.org/10.25367/cdatp.2021.2.p70-79.

Jevsnik, S.; Kalaoglu, F.; Terliksiz, S.; Purgaj, J. 2014. Review of computer models for fabric simulation. Tekstilec. 57, 4, 300-314. DOI: https://doi.org/10.14502/Tekstilec2014.57.300-314.

Xu, J.; Zhang, W. B.; Xiao, P. 2008. A study on impact factors of the distance eases between body and garment. 2008 9th International Conference on Computer-Aided Industrial Design and Conceptual Design, Beijing, China, Nov. 22-25, 2008, 201-205. DOI: https://doi.org/10.1109/CAIDCD.2008.4730551

Wong, A. S. W.; Li, Y.; Zhang, X. 2004. Influence of fabric mechanical property on clothing dynamic pressure distribution and pressure comfort on tight-fit sportswear. Sen’i Gakkaishi 60, 10, 293-299. DOI: https://doi.org/10.2115/fiber.60.293.

Dabolina, I.; Fomina, J.; Lapkovska, E.; Silina, L. 2020. Selected dynamic anthropometrics and body characteristics for posture corrector fit. Communications in Development and Assembling of Textile Products 1, 2, 96-103. DOI: https://doi.org/10.25367/cdatp.2020.1.p96-103.

Rödel, H.; Schenk, A.; Herzberg, C.; Krzywinski, S. 2001. Links between design, pattern development and fabric behaviours for clothes and technical textiles. International Journal of Clothing Science and Technology 13, 3/4, 217-227. DOI: https://doi.org/10.1108/EUM0000000005782.

Hallett, C.; Johnston, A. Fabric for Fashion: The Swatch Book, Laurence King Publishing, London, UHK, 2016.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Tibifez Hailu Nechno, Yordan Kyosev, Mulat Alubel, Sybille Krzywinski

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.