Investigation of an innvovative plating process in weft knitting

DOI:

https://doi.org/10.25367/cdatp.2025.6.p64-82Keywords:

Knitting, Plating, Innovative Yarn Supply, Layering, Novel Structures, Synchronised and Delayed Timing, Yarn Tension, Cam Depth, Multiply FabricAbstract

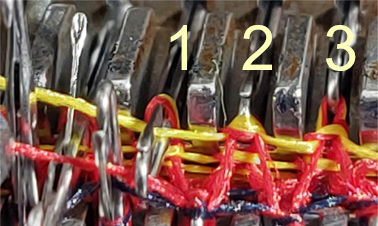

In a previous R&D project funded by the European Regional Development Fund (EFRE – 0400310), an innovative yarn feeding technology for weft knitting machines was validated. This technology employs three yarn carriers to create unique fabric structures: one carrier inserts yarn Y3 into both needle beds to produce a 1x1 rib pattern, while the other two carriers insert yarns exclusively into either the cylinder Y1 or dial needles Y2, resulting in a single jersey structure on each needle bed. This study investigates the effects of various machine settings on the plating results of knitted fabrics using this technology. Experiments were conducted to evaluate the impact of timing (synchronized and delayed), yarn tension, and cam depth on the fabric’s appearance. Color components of blue, yellow, and red were analyzed through stitch color counting and image processing with Matlab. Results indicated that synchronized timing increased the visibility of Y3, while delayed timing enhanced the prominence of Y1 on the technical front of the fabric. Increasing yarn tension of Y3 resulted in a noticeable color gradient. Adjustments in cam depth led to minor color changes. The study concluded that timing significantly affects the knitting result, with increased yarn tension of Y3 reducing its visibility on both sides of the fabric, while cam depth had less effect. These findings highlight the importance of precise machine settings in determining the final appearance of knitted fabrics, providing valuable insights for the textile industry in fabric design and production.

References

Venkatraman, P.D. Application of knitted fabrics in medical textiles. In: Advanced Knitting Technology. Maity, S., Rana, S., Pandit, P., Singha, K., Eds.; Woodhead Publishing: Duxford, 2022; pp. 471–502. DOI: 10.1016/B978-0-323-85534-1.00004-0.

Zhang, X.; Ma, P. Application of Knitting Structure Textiles in Medical Areas. Autex Research Journal 2018, 18, 181–191. DOI: 10.1515/aut-2017-0019.

Pavko-Čuden, A. Recent developments in knitting technology. In: Advanced Knitting Technology. Maity, S., Rana, S., Pandit, P., Singha, K., Eds.; Woodhead Publishing: Duxford, 2022; pp. 13–66. DOI: 10.1016/B978-0-323-85534-1.00020-9.

Power, E.J. Advanced knitting technologies for high-performance apparel. In: High-performance apparel: Materials, development, and applications. McLoughlin, J., Sabir, T., Eds.; Woodhead Publishing an imprint of Elsevier; The Textile Institute: Oxford, Cambridge, MA, Manchester, 2018; pp. 113–127. DOI: 10.1016/B978-0-08-100904-8.00005-5.

Manshahia, M.; Das, A. High active sportswear – A critical review. Indian Journal of Fibre & Textile Research (IJFTR) 2014, 39, 441–449. DOI: 10.56042/ijftr.v39i4.7733.

Troynikov, O.; Watson, C. Knitting technology for seamless sportswear. In: Textiles for sportswear. Shishoo, R., Ed.; The Textile Institute; Elsevier/WP Woodhead Publishing: Manchester, Amsterdam, Boston, Cambridge, Heidelberg, London, New York, Oxford, Paris, San Francisco, Singapore, Sydney, Tokyo, 2015; pp. 95–117. DOI: 10.1016/B978-1-78242-229-7.00005-9.

Araújo, M. de; Fangueiro, R.; Hu, H. Weft-knitted structures for industrial applications. In: Advances in Knitting Technology. Au, K.F., Ed.; Woodhead Publishing, 2011; pp. 136–170. DOI: 10.1533/9780857090621.2.136.

Peiner, C.G. Herstellung und Verarbeitung von 3D-Rundgestricken, 1st ed.; Shaker: Düren, 2022.

Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential fabric-reinforced composites: a comprehensive review. Journal of Materials Science 2021, 56, 14381–14415. DOI: 10.1007/s10853-021-06177-6.

Ramsgaard Thomson, M.; Tamke, M.; Karmon, A.; Underwood, J.; Gengnagel, C.; Stranghöner, N.; Uhlemann, J. Knit as bespoke material practice for architecture. In: Posthuman frontiers: data, designers, and cognitive machines: Proceedings of the 36th Annual Conference of the Association for Computer Aided Design in Architecture. Velikov, K., Ahlquist, S., Del Campo, M., Thün, G., Eds.; Association for Computer Aided Design in Architecture (ACADIA), 2016; pp. 280–289.

Pu, J.; Ma, K.; Luo, Y.; Tang, S.; Liu, T.; Liu, J.; Leung, M.; Yang, J.; Hui, R.; Xiong, Y.; Tao, X. Textile electronics for wearable applications. Int. J. Extrem. Manuf. 2023, 5, 42007. DOI: 10.1088/2631-7990/ace66a.

Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications. Advanced materials (Deerfield Beach, Fla.) 2014, 26, 5310–5336. DOI: 10.1002/adma.201400633.

Liu, X.; Miao, J.; Fan, Q.; Zhang, W.; Zuo, X.; Tian, M.; Zhu, S.; Zhang, X.; Qu, L. Recent Progress on Smart Fiber and Textile Based Wearable Strain Sensors: Materials, Fabrications and Applications. Adv. Fiber Mater. 2022, 4, 361–389. DOI: 10.1007/s42765-021-00126-3.

Singal, K.; Dimitriyev, M.S.; Gonzalez, S.E.; Cachine, A.P.; Quinn, S.; Matsumoto, E.A. Programming Mechanics in Knitted Materials, Stitch by Stitch. Nature Communications 2024. DOI: 10.48550/arXiv.2302.13467.

Hasani, H.; Hassanzadeh, S.; Abghary, M.J.; Omrani, E. Biaxial weft-knitted fabrics as composite reinforcements: A review. Journal of Industrial Textiles 2017, 46, 1439–1473. DOI: 10.1177/1528083715624256.

Akbari, M.; Jafari Nedoushan, R.; Dastan, T.; Hasani, H.; Yu, W.-R. Mechanical behavior of hybrid biaxial single jersey knitted-reinforced composites: Experimental and numerical approaches. Composite Structures, 2023, 319, 117167. DOI: 10.1016/j.compstruct.2023.117167.

Anand, S.C. Spacers - At the technical frontier. Knitting International 2003, 110, 38–41.

Dejene, B.K.; Gudayu, A.D. Exploring the potential of 3D woven and knitted spacer fabrics in technical textiles: A critical review. Journal of Industrial Textiles 2024, 54, 15280837241253614. DOI: 10.1177/15280837241253614.

Buzaite, V.; Repon, R.M.D.; Milasiene, D.; Mikucioniene, D. Development of multi-layered weft-knitted fabrics for thermal insulation. Journal of Industrial Textiles 2021, 51, 246–257. DOI: 10.1177/1528083719878811.

Buzaite, V.; Mikucioniene, D. Effect of inner layer structures of weft-knitted spacer fabrics on thermal insulation and air permeability. Textile Research Journal 2022, 92, 2862–2872. DOI: 10.1177/00405175211021452.

Qi, Y.; Li, J.; Liu, L. Tensile properties of multilayer-connected biaxial weft knitted fabric reinforced composites for carbon fibers. Materials & Design (1980-2015) 2014, 54, 678–685. DOI: 10.1016/j.matdes.2013.08.051.

Alpyildiz, T.; Rochery, M.; Kurbak, A.; Flambard, X. Stab and cut resistance of knitted structures: a comparative study. Textile Research Journal 2011, 81, 205–214. DOI: 10.1177/0040517510383617.

Liu, Y.; Hu, H. Sound Absorption Behavior of Knitted Spacer Fabrics. Textile Research Journal 2010, 80, 1949–1957. DOI: 10.1177/0040517510373639.

Dias, T.; Monaragala, R.; Needham, P.; Lay, E. Analysis of sound absorption of tuck spacer fabrics to reduce automotive noise. Measurement Science and Technology 2007, 18, 2657–2666. DOI: 10.1088/0957-0233/18/8/042.

Yu, A.; Matsui, Y.; Tonomura, K.; Ishii, Y. Development of knitted capacitive pressure sensor with spacer fabric structure. Mechanics of Advanced Materials and Structures 2023, 30, 4663–4670. DOI: 10.1080/15376494.2022.2103216.

Zhao, B.; Dong, Z.; Cong, H. A wearable and fully-textile capacitive sensor based on flat-knitted spacing fabric for human motions detection. Sensors and Actuators A: Physical 2022, 340, 113558. DOI: 10.1016/j.sna.2022.113558.

Mutschler, T.; Weber, M. Method and Knitting Machine for Producing a Knitted Material, and Knitted Material. WO2020069856 (A1), September 17, 2019.

Holderied, P.; Mutschler, T.; Tresp, S.; Klausmann, J.; Streitenberger, L.; Bueno, M.-A.; Weber, M.O. Development of a new yarn supply for weft knitting machines to produce innovative knitwear. CDATP 2023, 4, 51–60. DOI: 10.25367/cdatp.2023.4.p51-60.

Memminger-IRO. Data Sheet Electronic Yarn Feeder: EFS 920. https://www.memminger-iro.de/components/efs-920 (Accessed December 9, 2023).

Weber, M.O.; Weber, K.-P. Wirkerei und Strickerei: Ein Leitfaden für Industrie und Handel, 6th ed.; dfv Mediengruppe Fachbuch: Frankfurt am Main, 2016.

Filati Di.Vè. Technical Data Sheet: Waffle.

Pinkert machines UG (haftungsbeschränkt) & Co. KG. Pinkert machines. http://www.pinkert-machines.de/ (Accessed May 9, 2024).

Ray, S.C. Fundamentals and Advances in Knitting Technology; WPI India: Hoboken, 2015.

Spencer, D.J. Knitting technology: A comprehensive handbook and practical guide, 3rd ed.; Woodhead: Cambridge, 2001.

Wiedmaier, O.; Bühler, G. 3 Verbesserung der Plattiersicherheit beim Rundstricken/Improvement of accuracy in plating on circular knitting machine. Wirkerei- und Strickerei-Technik 1990, 40, 918–919.

Baozhu, K.; Weiyuan, Z. The optimal design of three-layer plated fabrics. Fibres and Textiles in Eastern Europe 2007, 15(1), 59-61.

Jian-xia, S.; Guang-li, S.; Guang-hua, L. Discussion on technology of knitting plating stitch with two yarn guides in the electronic Y-bed flat knitting machine. Wool Textile Journal 2012, 40, 12–15.

Schmidt, W. Plattierte R/L-Bindungen auf Großrundstrickmaschinen - die Möglichkeiten zur Musterung/Plated plain jersey at large circular knitting machines - capabilities of pattern designing. Maschen Industrie 1996, 46, 796–800.

Ray, S.C. Process control in knitting. In: Process Control in Textile Manufacturing. Majumdar, A., Das, A., Alagirusamy, R., Kothari, V.K., Eds.; Woodhead Publishing, 2013; pp. 243–264. DOI: 10.1533/9780857095633.3.243.

Bühler, G.; Wiedmaier, O. 1 Auswirkung des Fadenzulaufs auf die Qualität plattierter Rundstrickware/The effect of yarn supply on the quality of plated circular knitted fabrics. Maschen Industrie 1992, 42, 931–936.

Lipkow, I.A. Technologie der Wirk- und Strickwaren; Fachbuchverlag Leipzig: Leipzig, 1955.

Mayer & Cie. GmbH & Co. KG. User Manual Circular Knitting Machine FV2.0 (Accessed July 6, 2024).

Knapton, J.J.F.; Munden, D.L. A Study of the Mechanism of Loop Formation on Weft-Knitting Machinery: Part I: The Effect of Input Tension and Cam Setting on Loop Formation. Textile Research Journal 1966, 36, 1072–1080. DOI: 10.1177/004051756603601207.

Knapton, J.J.F.; Munden, D.L. A Study of the Mechanism of Loop Formation on Weft-Knitting Machinery: Part II: The Effect of Yarn Friction on Yarn Tension in Knitting and Loop Formation. Textile Research Journal 1966, 36, 1081–1091. DOI: 10.1177/004051756603601208.

Weber, M.O.; Ehrmann, A. Necessary modification of the Euler–Eytelwein formula for knitting machines. The Journal of The Textile Institute 2012, 103, 687–690. DOI: 10.1080/00405000.2011.598665.

Pusch, T.; Wünsch, I.; Offermann, P. Dynamics of yarn tension on knitting machines. Autex Research Journal 2000, 1, 54–63. DOI: 10.1515/aut-2000-010202.

Iqbal, W.; Jiang, Y.; Siddiqui, M.O.R.; Ahmed, R.; Yi-Xong, Q.; Afzal, S.U.; Gunasekarag, D.S.W.; Hussain, R. The Measurement of Dynamic Tension Fluctuation in a Flat Knittin

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Prisca Holderied, Marie-Ange Bueno, Thomas Mutschler, Marcus O. Weber

This work is licensed under a Creative Commons Attribution 4.0 International License.