Evaluation of the surface quality of spun materials using topothesy

DOI:

https://doi.org/10.25367/cdatp.2021.2.p208-216Abstract

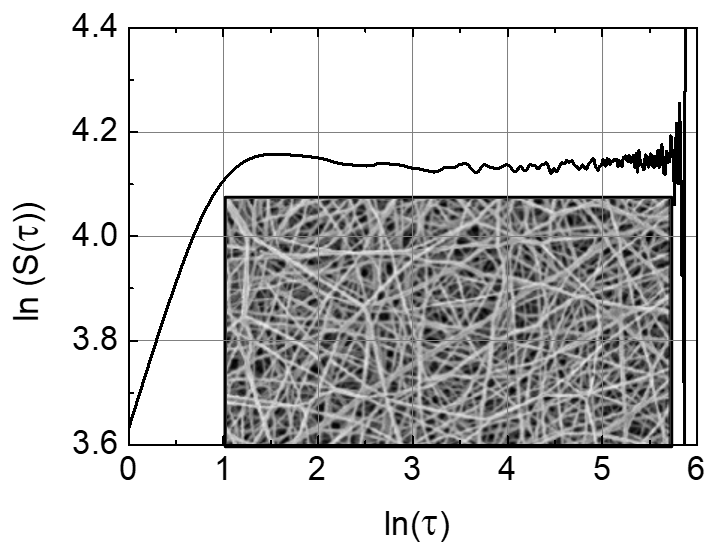

Topothesy and fractal dimensions were calculated for poly(acrylonitrile) (PAN) nanofibers mats obtained by electrospinning. These methods enable quantitatively describing and thus comparing solid-state surfaces and detecting fabric errors. The obtained variety of structural properties results from different substrates and after-treatments, e.g. stabilization and carbonization. The change in spatial morphology was reported for different magnification of images obtained with the use of Helium Ion Microscopy (HIM).

References

Andreychouk, V.; Blachowicz, T.; Domino, K. Fractal dimension of cave for exemplary gypsum cave-mazes of Western Ukraine. Landform Analysis 2013, 22, 3-8. DOI: https://doi.org/10.12657/landfana.022.001.

Ehrmann, A.; Blachowicz, T. (2017) Image Processing Techniques for Evaluation of Textile Materials. In: Examination of Textiles with Mathematical and Physical Methods. Springer, Cham. DOI: https://doi.org/10.1007/978-3-319-47408-3_7.

Melo de, R.H.C.; Conci, A. How succolarity could be used as another fractal measure in image analysis. Telecommunication Systems 2011, 52, 1643-1655. DOI: https://doi.org/10.1007/s11235-011-9657-3.

Grzybowski, J.; Blachowicz, T. Estimation of spatial distribution and symmetry of textile materials using lacunarity. CDATP 2020, 1, 180-185. DOI: https://doi.org/10.25367/cdatp.2020.1.

Hanmandlu, M.; Choudhury, D.; Dash, S. Detection of defects in fabrics using topothesy fractal dimension features. SIViP 2014, 9, 1521-1530. DOI: https://doi.org/10.1007/s11760-013-0604-5.

Thomas, T. R.; Rosén, B.-G.; Amini, N. Fractal characterisation of the anisotropy of rough surfaces. Wear 1999, 232, 41-50. DOI: https://doi.org/10.1016/S0043-1648(99)00128-3

Thomas, T. R.; Rosén, B.-G. Determination of the optimum sampling interval for rough contact mechanics. Tribology International 2000, 33, 601-610. DOI: https://doi.org/10.1016/S0301-679X(00)00076-1.

Russ, J. C. Fractal geometry in engineering metrology. In: Mainsah, E.; Greenwood, J. A.; Chetwynd, D. G. (eds.), Metrology and Properties of Engineering Surfaces, Springer, Boston, MA. DOI: https://doi.org/10.1007/978-1-4757-3369-3_2.

Hanmandlu, M.; Mittal, N.; Vijay, R. A robust finger knuckle print authentication using topothesy and fractal dimension. Defence Science Journal 2017, 67, 66-73. DOI: https://doi.org/10.14429/dsj.67.9003

Ngan, H. Y. T.; Pang, G. K. H.; Yung, N. H. C. Automated fabric defect detection—A review. Image and Vision Computing 2011, 29, 442-458. DOI: https://doi.org/10.1016/j.imavis.2011.02.002.

Militký, J.; Bajzík, V. Surface roughness and fractal dimension. The Journal of the Textile Institute 2001, 92, 91-113. DOI: https://doi.org/10.1080/00405000108659617.

Blachowicz, T.; Böhm, T.; Grzybowski, J.; Domino, K.; Ehrmann, A. Analysis of AFM images of nanofibre mats for automated processing. Tekstilec 2020, 63, 104-112. DOI: https://doi.org/10.14502/Tekstilec2020.63.94-103.

Conci, A.; Proenca, C. B. A comparison between image-processing approaches to textile inspection. The Journal of The Textile Institute 2000, 91, 317-323. DOI: https://doi.org/10.1080/00405000008659509.

Javed, A.; Mirza, A. U. Comparative analysis of different fabric defects detection techniques. I. J. Image, Graphics and Signal Processing 2013, 1, 40-45. DOI: https://doi.org/10.5815/ijigsp.2013.01.06.

Storck, J. L.; Hellert, Ch.; Brockhagen, B.; Wortmann, M.; Diestelhorst, E.; Frese, N.; Grothe, T.; Ehrmann, A. Metallic supports accelerate carbonization and improve morphological stability of polyacrylonitrile nanofibers during heat treatment. Materials 2021, 14, 4686. DOI: https://doi.org/10.3390/ma14164686.

Russ, J. C. Fractal surfaces, Plenum Press, New York 1994.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Tomasz Blachowicz, Michal Koruszowic

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.