Effect of micro phase change materials on the thermal behavior of leather

DOI:

https://doi.org/10.25367/cdatp.2023.4.p242-250Keywords:

PCM, thermal comfort, leather finishing, thermoregulatingAbstract

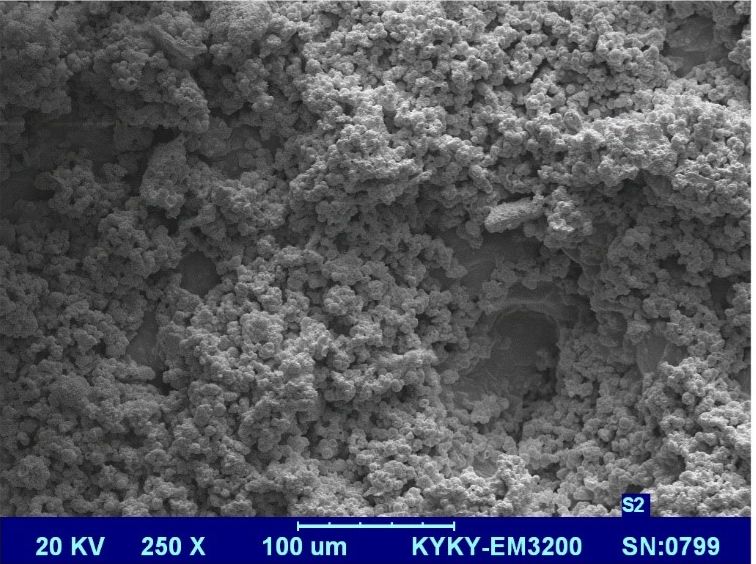

Today, scientists are interested in the manufacturing and invention of smart textiles such as phase change materials (PCMs). The process of phase change from solid to liquid and vice versa takes place in such materials. Using materials such as PCM could change the properties of leather for better performance, and could be applied to many places such as the shoe industry. The background of the study is that using PCMs could increase thermoregulating properties of materials. For finishing leather with PCMs, several methods were suggested such as spraying, tanning, laminating, etc. In this study, first impregnated leather with 5% and 10% of PCM by spray technic are prepared and characterized using scanning electron microscopy (SEM) and differential scanning calorimetry (DSC). Finally, water vapor permeability and physical properties of the samples were analyzed for an understanding of leather comfort. The results reveal that after impregnating with 10% PCMs, significant effects on the thermal behavior of samples were observed, and this finishing had no effect on the comfort of leather.

References

Batina, J.; Blancher, S.; Kouskou, T. Modelling of a Phase Change Material melting process heated from below using spectral collocation methods. International Journal of Numerical Methods for Heat & Fluid Flow 2014, 24 (3), 697-734. DOI: https://doi.org/10.1108/HFF-03-2012-0062.

Salaün, F.; Devaux, E.; Bourbigot, S.; Rumeau, P.; Chapuis, P.-O.; Saha, S. K.; Volz, S. Polymer nanoparticles to decrease thermal conductivity of phase change materials. Thermochimica Acta. 2008; 477(1-2):25-31. DOI: https://doi.org/10.1108/HFF-03-2012-0062.

Jima, W. D.; Dada, T. K.; Palanisamy, T. Cool garment leathers for hot environment. Journal of Thermal Analysis and Calorimetry 2019; 135 (6), 3289-3295. DOI: https://doi.org/10.1007/s10973-018-7569-0.

Khan, M.; Chandra, S.; Vasishtha, A. Leather finishes based on polyvinylchloride and polystyrene resins. Pigment & Resin Technology 1981, 10 (1), 12-15. DOI: https://doi.org/10.1108/eb041659.

Kumar, N.; Gupta, S. K. Progress and application of phase change material in solar thermal energy: An overview. Materials Today: Proceedings 2021, 44, 271-281. DOI: https://doi.org/10.1016/j.matpr.2020.09.465.

Kumar, N.; Gupta, S. K.; Sharma, V. K. Application of phase change material for thermal energy storage: An overview of recent advances. Materials Today: Proceedings 2021, 44, 368-375. DOI: https://doi.org/10.1016/j.matpr.2020.09.745.

Yang, K.; Venkataraman, M.; Zhang, X.; Wiener, J.; Zhu, G.; Yao, J.; et al. Incorporation of organic PCMs into textiles. Journal of Materials Science 2022, 57 (2), 798-847. DOI: https://doi.org/10.1007/s10853-021-06641-3.

Nazemi, S.; Khajavi, R.; Far, H. R.; Yazdanshenas, M. E.; Raad, M. Effect of hydrophobic finishing on drag force of swimwear. International Journal of Clothing Science and Technology 2017, 30 (1), 2-15. DOI: https://doi.org/10.1108/IJCST-09-2016-0109.

Nazemi, S.; Khajavi, R.; Far, H. R.; Yazdanshenas, M. E.; Raad, M. Modeling and simulation of drag force for coated PET fabric with silica nano particles. International Journal of Clothing Science and Technology 2018, 30 (3), 398-411. DOI: https://doi.org/10.1108/IJCST-09-2017-0139.

Jiang, S.; Miao, D.; Zhao, D. Adhesive properties of SS to PU and PVC leathers. International Journal of Clothing Science and Technology 2014, 26 (2), 108-117. DOI: https://doi.org/10.1108/IJCST-08-2012-0052.

Huang, X.; Zhu, C.; Lin, Y.; Fang, G. Thermal properties and applications of microencapsulated PCM for thermal energy storage: A review. Applied Thermal Engineering 2019, 147 (1), 841-855. DOI: https://doi.org/10.1016/j.applthermaleng.2018.11.007.

Bagherzadeh, R.; Montazer, M.; Latifi, M.; Sheikhzadeh, M.; Sattari, M. Evaluation of comfort properties of polyester knitted spacer fabrics finished with water repellent and antimicrobial agents. Fibers and Polymers 2007, 8 (1), 386-392. DOI: https://doi.org/10.1007/BF02875827.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Siamak Nazemi, Rohollah Bagherzade, Mohsen Gorji

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.