Investigation on a smart textile heating concept for energy consumption-optimised heat transfer

DOI:

https://doi.org/10.25367/cdatp.2024.5.p234-241Keywords:

e-textiles, smart textiles, heating, energy efficiency, integration techniqueAbstract

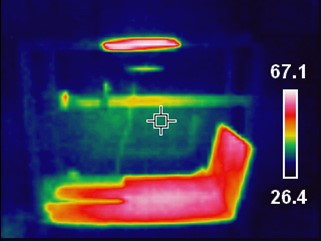

Conventional non-stationary artificial heating methods, such as infrared radiators, have various deficits: The heat fields are small, their range is short, and the installation options are limited. In addition, they are environmentally harmful due to high emissions. To make in- and outdoor areas usable at lower temperatures, an energy consumption-optimized heat transfer is required. In this work we are investigating on an innovative, intelligent, modular textile for indoor and outdoor use. The use of conductive wires, sensors and a data-driven control circuit in the textile enables targeted heat radiation, which can be expanded as required thanks to its modular design. This reduces emissions and precisely controls energy consumption. By developing a demonstrator, the concept of the layered structure of the textile module, including unidirectional radiation and sensor technology, is being investigated. The conductive wires are incorporated into a flexible carrier material using a modified embroidery machine. In the process, the carrier material must meet the previously defined design requirements that are based on the material investigation and preliminary tests on embroidery feasibility. The structure of the intelligent textile is constructed, realized as a prototype, and validated. Through the combination of a heat source and flexible support material, it is possible to bring a competitive product to the market.

References

Europe Heating Radiators Market Share, Size & Growth Report | 2031. https://www.skyquestt.com/report/europe-heating-radiators-market.

Wetter.de. Der Heizpilz des Grauens: Die Wärmestrahler sind riesige Energiefresser und CO2-Produzenten. wetter.de. November 1, 2016. https://www.wetter.de/cms/der-heizpilz-des-grauens-die-waermestrahler-sind-riesige-energiefresser-und-co2-produzenten-4028985.html.

Channel, W. Heiße Luft? So steht es um die Energiebilanz von Heizpilzen | The Weather Channel. The Weather Channel. October 18, 2020. https://weather.com/de-DE/wissen/klima/news/2020-10-18-heisse-luft-so-steht-es-um-die-energiebilanz-von-heizpilzen.

Schuberth, J.; Börner, M.; Umweltbundesamt. TERRASSENHEIZSTRAHLER Informationen über die nachteiligen Umweltwirkungen; Umweltbundesamt, 2009. https://www.umweltbundesamt.de/sites/default/files/medien/publikation/long/3735.pdf.

Ceramicx Ltd. Preferred infrared wavelengths for comfort heating – White papers – Ceramicx. Ceramicx. https://www.ceramicx.com/information/media/white-papers/preferred-wavelengths-for-comfort-heating/.

Dittmann, A.; Fischer, S.; Huhn, J.; Klinger, J. Repetitorium der Technischen Thermodynamik; Vieweg+Teubner Verlag Wiesbaden, 1995. DOI: https://doi.org/10.1007/978-3-322-94059-9.

Wu, H.; Tan, S.; Zheng, X.; Zhao, Z.; Wang, M.; Ma, Q.; Wu, J.; Li, D. Fabrication of carbon fiber/cement composites with controllable precise patterned structures via facile computerized embroidery. Materials & Design 2024, 242, 113017. DOI: https://doi.org/10.1016/j.matdes.2024.113017.

Yang, Y.; Chen, D.; Cheng, Y.; Sun, B.; Zhao, G.; Fei, W.; Han, W.; Han, J.; Zhang, X. Eco-friendly and sustainable approach of assembling sugars into biobased carbon fibers. Green Chemistry 2022, 24(13), 5097–5106. DOI: https://doi.org/10.1039/d2gc01075e.

Li, X.; Zhao, L.; He, T.; Zhang, M.; Wang, Z.; Zhang, B.; Weng, X. Highly conductive, hierarchical porous ultra-fine carbon fibers derived from polyacrylonitrile/polymethylmethacrylate/needle coke as binder-free electrodes for high-performance supercapacitors. Journal of Power Sources 2022, 521, 230943. DOI: https://doi.org/10.1016/j.jpowsour.2021.230943.

Alshabouna, F.; Lee, H. S.; Barandun, G.; Tan, E.; Cotur, Y.; Asfour, T.; Gonzalez-Macia, L.; Coatsworth, P.; Núnez-Bajo, E.; Kim, J.-S.; Güder, F. PEDOT:PSS-modified cotton conductive thread for mass manufacturing of textile-based electrical wearable sensors by computerized embroidery. Materials Today 2022, 59, 56–67. DOI: https://doi.org/10.1016/j.mattod.2022.07.015.

Huang, Q.; Wang, D.; Hu, H.; Shang, J.; Chang, J.; Xie, C.; Yang, Y.; Lepró, X.; Baughman, R. H.; Zheng, Z. Additive functionalization and embroidery for manufacturing wearable and washable textile supercapacitors. Advanced Functional Materials 2020, 30(27), 1910541. DOI: https://doi.org/10.1002/adfm.201910541.

Zheng, Y.; Jin, L.; Qi, J.; Liu, Z.; Xu, L.; Hayes, S.; Gill, S.; Li, Y. Performance evaluation of conductive tracks in fabricating e-textiles by lock-stitch embroidery. Journal of Industrial Textiles 2020, 51, 6864S-6883S. DOI: https://doi.org/10.1177/1528083720937289.

Ahn, J.; Kim, S. Automated Textile Circuit Generation using Machine Vision and Embroidery Technique. Textile Research Journal 2022, 92(11–12), 1977–1986. DOI: https://doi.org/10.1177/00405175221075062.

Konzilia, J.; Wachter, J.; Egger, M.; Waltl, C.; Fröis, T.; Bechtold, T.; Feix, J. Embroidered carbon reinforcement for concrete. Buildings 2023, 13(9), 2293. DOI: https://doi.org/10.3390/buildings13092293.

Dong, X.-X.; Cao, Y.-M.; Wang, C.; Wu, B.; Zheng, M.; Xue, Y.-B.; Li, W.; Han, B.; Zheng, M.; Wang, Z.-S.; Zhuo, M.-P. MXene-Decorated Smart Textiles with the Desired Mid-Infrared Emissivity for Passive Personal Thermal Management. ACS Applied Materials & Interfaces 2023, 15(9), 12032–12040. DOI: https://doi.org/10.1021/acsami.2c21696.

Inverse Square Law – Statement, Formula and applications. BYJUS. https://byjus.com/physics/inverse-square-law/.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Robin Oberlé, Robert T. Boich, Brikena Shazimani, Thomas Gries

This work is licensed under a Creative Commons Attribution 4.0 International License.