Validation of devices for characterization of hybrid 3D printed embroidery TENG for energy harvesting

DOI:

https://doi.org/10.25367/cdatp.2022.3.p1-8Keywords:

Hybrid nanogenerator, flexible filament, 3D printing, embroidery, tapping characterization, conductive, multifilament, hybrid yarn,Abstract

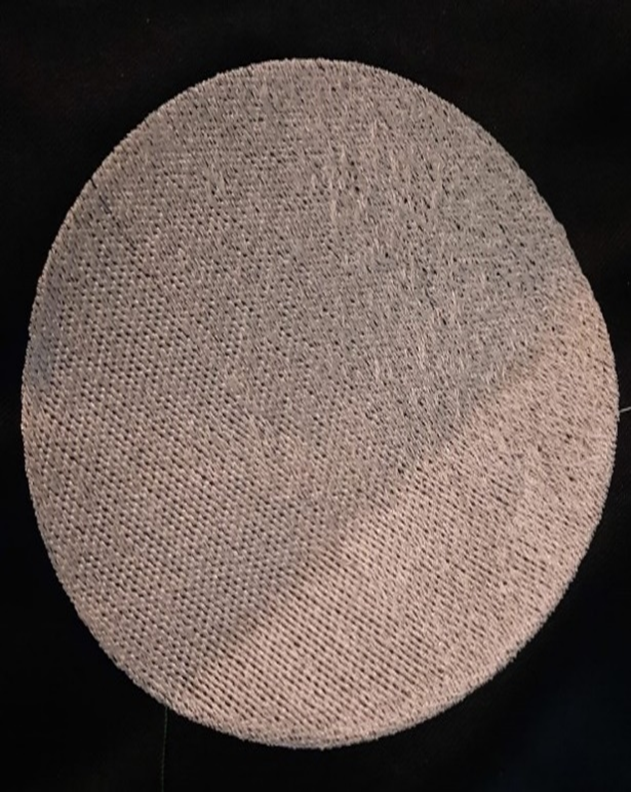

A textile-based triboelectric nanogenerator (TENG) is an energy harvesting flexible and lightweight device that converts mechanical energy to electrical energy. This work presents characterization of a novel hybrid 3D printed embroidery TENG for energy harvesting. The digital embroidery part is done on Brother Embroidery Machine PR670E with polyester multifilament conductive hybrid thread (CleverTex) with a linear thread resistance of 280 Ω/m. This embroidery thread is fully compatible with the standard textile embroidery process. The thread is highly suitable for embroidery due to its very good mechanical properties and no loop formation during embroidery. These features make the thread especially suitable for high production quality. It could be used as needle thread or bobbin thread. For the preparation of the embroidery part, the polyester multifilament conductive hybrid thread is used as needle thread with 100% polyester Madeira thread as bobbin thread. These threads have non-toxic, non-skin irritation properties, which makes them suitable for smart wearable energy harvesting applications. Furthermore, these threads are coated with silicone-paraffin emulsions that improve their running during the embroidery process. Among the possible stitch types (satin, fill, prog. fill, piping, motif, cross, concentric circle, radial, spiral, flexible spiral, stippling, net fill, zigzag net fill, and decorative fill), fill stitch with medium stitch density and 4.5 lines per mm has been used to develop this energy harvesting sample. The 3D printed textile fabric is prepared with extremely flexible filament with a tensile elongation at break of 1400%. The output voltage is 200 V and 103 V for tapping and friction characterization, respectively

References

Fan, F.-R.; Tian, Z.-Q.; Wang, Z. L. Flexible triboelectric generator. Nano Energy 2012, 1 (2), 328-334. DOI: https://doi.org/10.1016/j.nanoen.2012.01.004.

Wu, C. S.; Wang, A. C.; Ding, W. B.; Guo, H. Y.; Wang, Z. L. Triboelectric nanogenerator: a foundation of the energy for the new era. Advanced Energy Materials 2019. 9 (1), 1802906. DOI: https://doi.org/10.1002/aenm.201802906.

Smallwood, J. Reducing static electricity in carpets, in Advances in carpet manufacture; Elsevier, 2018; pp. 135-162. DOI: https://doi.org/10.1016/B978-0-08-101131-7.00008-3.

Tani, H.; Sugimoto, M.; Fushihara, K.; Nakao, Y.; Renguo, R.; Koganezawa, S.; Tagawa. Energy harvesting from triboelectric nanogenerator attached inside folling tire. In 2019 19th International Conference on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS). 2019. DOI: https://doi.org/10.1109/PowerMEMS49317.2019.002.

Wang, Z. L.; Jiang, T.; Xu, L. Toward the blue energy dream by triboelectric nanogenerator networks. Nano Energy 2017, 39, 9-23. DOI: https://doi.org/10.1016/j.nanoen.2017.06.035.

Wang, Z. L. Triboelectric nanogenerator (TENG) – sparking an energy and sensor revolution. Advanced Energy Materials 2020. 10 (17), 2000137. DOI: https://doi.org/10.1002/aenm.202000137.

Bera, B. Literature review on triboelectric nanogenerator. Imperial Journal of Interdisciplinary Research (IJIR) 2016, 2 (10), 1263-1271.

Repoulias, A.; Vassiliadis, S.; Galata, S. F. Triboelectricity and textile structures. The Journal of The Textile Institute 2021, 112 (10), 1580-1587. DOI: https://doi.org/10.1080/00405000.2020.1829331.

Paosangthong, W.; Torah, R.; Beeby, S. Recent progress on textile-based triboelectric nanogenerators. Nano Energy 2019, 55, 401-423. DOI: https://doi.org/10.1016/j.nanoen.2018.10.036.

Rathore, S.; Sharma, S.; Swain, B. P.; Ghadai, R. Kr. A critical review on triboelectric nanogenerator. IOP Conf. Ser.: Mater. Sci. Eng. 2018, 377, 012186.

Jung, W.-S.; Kang, M.-G.; Moon, H. G.; Baek, S-H.; Yoon, S.-J.; Wang, Z.-L.; Kim, S.-W.; Kang, C.-Y. High output piezo/triboelectric hybrid generator. Scientific Reports 2015. 5 (1), 9309. DOI: https://doi.org/10.1038/srep09309

Pyo, S.; Kim, M.-Ol; Kwon, D.-S.; Kim, W. D.; Yang, J.-H.; Cho, H. S.; Lee, J. H.; Kim, J. B. All-textile wearable triboelectric nanogenerator using pile-embroidered fibers for enhancing output power. Smart Materials and Structures 2020. 29 (5), 055026. DOI: https://doi.org/10.1088/1361-665X/ab710a.

Cui, N. Y.; Gu, L.; Lei, Y. M.; Liu, J. M.; Qin, Y.; Ma, X. H.; Hao, Y.; Wang, Z. L. Dynamic behavior of the triboelectric charges and structural optimization of the friction layer for a triboelectric nanogenerator. ACS Nano 2016, 10 (6), 6131-6138. DOI: https://doi.org/10.1021/acsnano.6b02076.

Xia, K. Q.; Zhu, Z. Y.; Zhang, H. Z.; Du, C. L.; Xu, Z. W.; Wang, R. J. Painting a high-output triboelectric nanogenerator on paper for harvesting energy from human body motion. Nano Energy 2018, 50, 571-580. DOI: https://doi.org/10.1016/j.nanoen.2018.06.019.

Zhou, T., Zhang, C.; Han, C. B.; Fan, F. R.; Tang, W.; Wang, Z. L. Woven structured triboelectric nanogenerator for wearable devices. ACS Applied Materials & Interfaces 2014, 6 (16), 14695-14701. DOI: https://doi.org/10.1021/am504110u.

Xing, F.; Jie, Y.; Cao, X.; Li, T.; Wang, N. Natural triboelectric nanogenerator based on soles for harvesting low-frequency walking energy. Nano Energy 2017, 42, 138-142. DOI: https://doi.org/10.1016/j.nanoen.2017.10.029.

Tahir, H. R.; Malengier, B.; van Daele, D.; van Langenhove, L. Validation of a platform for the electrostatic characterization of textile. Electronics 2022, 11 (1), 115. DOI: https://doi.org/10.3390/electronics11010115.

Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric nanogenerator: Structure, mechanism, and applications. ACS Nano 2021, 15 (1), 258-287. DOI: https://doi.org/10.1021/acsnano.0c09803.

Zhu, G.; Peng, B.; Chen, J.; Jing, Q. S.; Wang, Z. L. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126-138. DOI: https://doi.org/10.1016/j.nanoen.2014.11.050.

Seol, M.; Kim, S. S.; Cho, Y. C.; Byun, K.-E.; Kim, H. Y.; Kim, J. H.; Kim, S. K.; Kim, S.-W.; Shin, H.-J.; Park, S. J. Triboelectric series of 2D layered materials. Advanced Materials 2018, 30 (39), 1801210. DOI: https://doi.org/10.1002/adma.201801210.

Zou, H. Y.; Zhang, Y.; Guo, L. T.; Wang, P. H.; He, X.; Dai, G. Z.; Zheng, H. W.; Chen, C. Y.; Wang, A. C.; Xu, C.; Wang, Z. L. Quantifying the triboelectric series. Nature Communications 2019, 10 (1), 1427. DOI: https://doi.org/10.1038/s41467-019-09461-x.

Zou, H. Y.; Guo, L. T.; Xue, H.; Zhang, Y.; Shen, X. F.; Liu, X. T.; Wang, P. H.; He, X.; Dai, G. Z.; Jiang, P.; Zheng, H. W.; Zhang, B. B.; Xu, C.; Wang, Z. L. Quantifying and understanding the triboelectric series of inorganic non-metallic materials. Nature Communications 2020, 11 (1), 2093. DOI: https://doi.org/10.1038/s41467-020-15926-1

Chen, B. D.; Tang, W.; Jiang, T.; Zhu, L. P.; Chen, X. G.; He, C.; Xu, L.; Guo, H. G.; Lin, P.; Li, D.; Shao, J. J.; Wang, Z. L. Three-dimensional ultraflexible triboelectric nanogenerator made by 3D printing. Nano Energy 2018, 45, 380-389. DOI: https://doi.org/10.1016/j.nanoen.2017.12.049.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Hasan Tahir, Benny Malengier, Carla Hertleer, Lieva Van Langenhove

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.