Auxetic structures from 3D printed hybrid textiles

DOI:

https://doi.org/10.25367/cdatp.2021.2.p91-102Keywords:

auxetic, 4d textiles, 3d printing, knitsAbstract

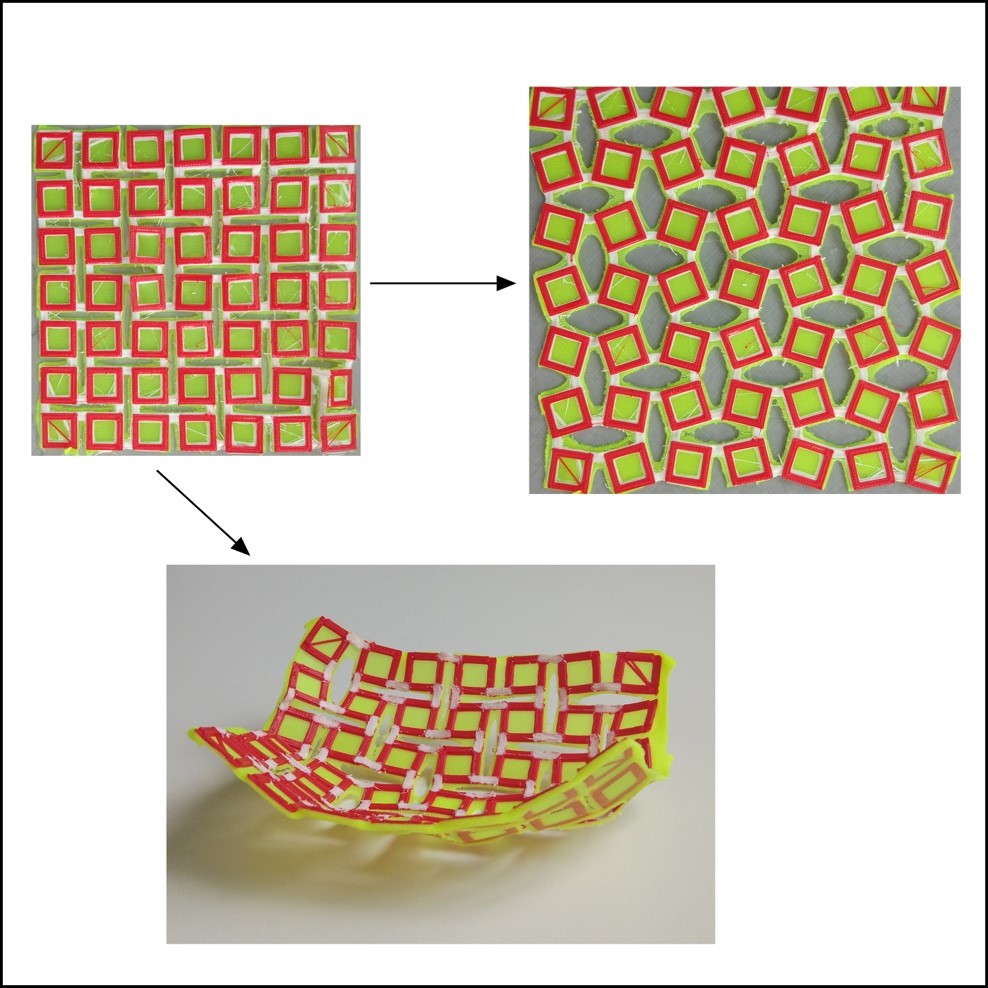

Auxetic structures have been produced using 3D printing and knitted textile materials. A review of other auxetic textiles is presented along with the new materials. A range of configurations were developed, prototyped, and tested to demonstrate significant auxetic response, including Poisson’s ratio up to negative one. The concept of 4D textiles was employed to create environmentally responsive hinges in some structures, allowing the material to change shape in response to thermal stimulus.

References

S.D. Poisson. 1827. Note sur l’Extension des Fils et des Plaques élastiques. Annales de Chimnie et Physique 36, 384-387.

R. Lakes. 1987. Foam Structures with a Negative Poisson’s Ratio. Science 235, 4792, 1038.1040. DOI: https://doi.org/10.1126/science.235.4792.1038.

K. E. Evans. 1991. Auxetic polymers: a new range of materials. Endeavour 15, 4, 170-174. DOI: https://doi.org/10.1016/0160-9327(91)90123-S.

J.N. Grima and K.E. Evans. 2006. Auxetic behavior from rotating triangles. Journal of Materials Science 41, 10, 3193-3196. DOI: https://doi.org/10.1007/s10853-006-6339-8.

J.N. Grima and K.E. Evans. 2000. Auxetic behavior from rotating squares. Journal of Materials Science Letters 19, 17, 1563-1565. DOI: https://doi.org/10.1023/A:1006781224002.

N. Ravirala, A. Alderson, and K.L. Alderson. 2007. Interlocking hexagons model for auxetic behaviour. Journal of Materials Science 42, 17, 7433-7445. DOI: https://doi.org/10.1007/s10853-007-1583-0.

M. Mir, M. N. Ali, J. Sami, and U. Ansari. 2014. Review of Mechanics and Applications of Auxetic Structures. Advances in Materials Science and Engineering 2014, 753496. DOI: https://doi.org/10.1155/2014/753496.

M. Sanami, N. Ravirala, K. Alderson, and A. Alderson. 2014. Auxetic Materials for Sports Applications. Procedia Engineering 72, 453-458. DOI: https://doi.org/10.1016/j.proeng.2014.06.079.

Z. Wang and H. Hu. 2014. Auxetic materials and their potential applications in textiles. Textile Research Journal 84, 15, 1600-1611. DOI: https://doi.org/10.1177/0040517512449051.

Y. Prawoto. 2012. Seeing auxetic materials from the mechanics point of view: A structural review on the negative Poisson’s ratio. Computational Materials Science 58, 140-153. DOI: https://doi.org/10.1016/j.commatsci.2012.02.012.

G. E. Stavroulakis. 2005. Auxetic behaviour: appearance and engineering applications. physica status solidi (b) 242, 3, 710-720. DOI: https://doi.org/10.1002/pssb.200460388.

C. W. Smith, J. N. Grima, and K. E. Evans. 2000. A novel mechanism for generating auxetic behaviour in reticulated foams: missing rib foam model. Acta Materialia 48, 17, 4349-4356. DOI: https://doi.org/10.1016/S1359-6454(00)00269-X.

M. R. Sloan, J. R. Wright, and K. E. Evans. 2011. The helical auxetic yarn – A novel structure for composites and textiles; geometry, manufacture and mechanical properties. Mechanics of Materials 43, 9, 476-486. DOI: https://doi.org/10.1016/j.mechmat.2011.05.003.

J. R. Wright, M. K. Burns, E. James, M. R. Sloan, and K. E. Evans. 2012. On the design and characterisation of low-stiffness auxetic yarns and fabrics. Textile Research Journal 82, 7, 645-654. DOI: https://doi.org/10.1177/0040517512436824.

D. Rant, T. Rijavec, and A. Pavko-Çuden. 2013. Auxetic Textiles. Act Chimica Slovenica 60, 4, 715-723.

S. C. Ugbolue, Y. K. Kim, S. B. Warner, Q. Fan, C.-L. Yang, O. Kyzymchuk, and Y. Feng. 2010. The formation and performance of auxetic textiles. Part I: theoretical and technical considerations. Journal of the Textile Institute 101, 7, 660-667. DOI: https://doi.org/10.1080/00405000902733790.

C. Ugbolue, S., K. Kim, Y. and B. Warner, S. 2012. Engineered Warp Knit Auxetic Fabrics. Journal of Textile Science & Engineering 2, 1, 1000e103. DOI: https://doi.org/10.4172/2165-8064.1000e103.

M. Starbuck, S. C. Anand, N. Ravirala, K. Alderson, and A. Alderson, 2008. Fabrics having knit structures exhibiting auxetic properties and garments formed thereby. Patent No. US 20080011021 A1, Jan. 17, 2008.

Z. Wang and H. Hu. 2017. Tensile and forming properties of auxetic warp-knitted spacer fabrics. Textile Research Journal 87, 16, 1925-1937. DOI: https://doi.org/10.1177/0040517516660889.

S. C. Anand and D. Skertchly. 2010. Auxetic knitted fabric. Patent No. WO 2010125397 A1, Nov. 4, 2010.

P. Verma, M. L. Shofner, A. Lin, K. B. Wagner, and A. C. Griffin. 2015. Inducing out-of-plane auxetic behavior in needle-punched nonwovens. physica status solidi (b) 252, 7, 1455-1464. DOI: https://doi.org/10.1002/pssb.201552036.

S.M. Felton, M. T. Tolley, B. Shin, C. D. Onal, E. D. Demaine, D. Rus, and R. J. Wood. 2013. Self-folding with shape memory composites. Soft Matter 9, 32, 7688. DOI: https://doi.org/10.1039/c3sm51003d.

E. A. Peraza-Hernandez, D. J. Hartl, R. J. Malak Jr,, and D. C. Lagoudas. 2014. Origami-inspired active structures: A synthesis and review. Smart Materials and Structures 23, 9, 094001. DOI: https://doi.org/10.1088/0964-1726/23/9/094001.

V. Turk. 2015. Space Origami Could Pack Big Structures into Tiny Satellites. Retrieved August 14, 2021 from https://www.vice.com/en/article/ezp4mm/space-origami-could-pack-big-structures-into-tiny-satellites.

Y. Liu, H. Hu, J. K. C. Lam, and S. Liu. 2010. Negative Poisson’s Ratio Weft-knitted Fabrics. Textile Research Journal 80, 9, 856-863. DOI: https://doi.org/10.1177/0040517509349788.

G. J. Brinks, M. M. C. Warmöskerken, R. Akkerman, and W. Zweers. 2013. The added value of 3D polymer deposition on textiles. Proc. of 13th AUTEX World Textile Conference, Dresden, Germany.

E. Pei, J. Shen, and J. Watling. 2015. Direct 3D printing of polymers onto textiles: Experimental studies and applications. Rapid Prototyping Journal 21, 5, 556-571. DOI: https://doi.org/10.1108/RPJ-09-2014-0126.

L. Sabantina, F. Kinzel, A. Ehrmann, and K. Finsterbusch. 2015. Combining 3D printed forms with textile structures - mechanical and geometrical properties of multi-material systems. IOP Conference Series: Materials Science and Engineering 87, 012005. DOI: https://doi.org/10.1088/1757-899X/87/1/012005.

D. Schmelzeisen, H. Koch, and C. Pastore. 2018. 4D-Textiles: Hybrid textile structures that change structural form with time. In Y. Kyosev, Mahltig, B., and A. Schwarz-Pfeiffer (Eds.). Narrow Fabrics and Smart Textiles. Springer International Publishing.

K. Simonis, D. Schmelzeisen, V. Gesché, and T. Gries. 2017. 4D textiles: application in sports industry. Future Textiles 2, 2, 38-39.

A. Narula, C. M. Pastore, D. Schmelzeisen, S. El Basri, J. Schenk, and S. Shajoo. 2018. Effect of knit and print parameters on peel strength of hybrid 3-D printed textiles. Journal of Textiles and Fibrous Materials 1, 251522111774925. DOI: https://doi.org/10.1177/2515221117749251.

R. Melnikova, A. Ehrmann, and K. Finsterbusch. 2014. 3D printing of textile-based structures by fused deposition modelling (FDM) with different polymer materials. IOP Conference Series: Materials Science and Engineering 62, 012018. DOI: https://doi.org/10.1088/1757-899X/62/1/012018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Subin Shajoo, David Schmelzeisen, Christopher Pastore

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.