Comparison of FDM and SLA printing on woven fabrics

DOI:

https://doi.org/10.25367/cdatp.2024.5.p169-177Keywords:

3D printing, fused deposition modeling (FDM), stereolithography (SLA), adhesion, textile fabric, woven fabricAbstract

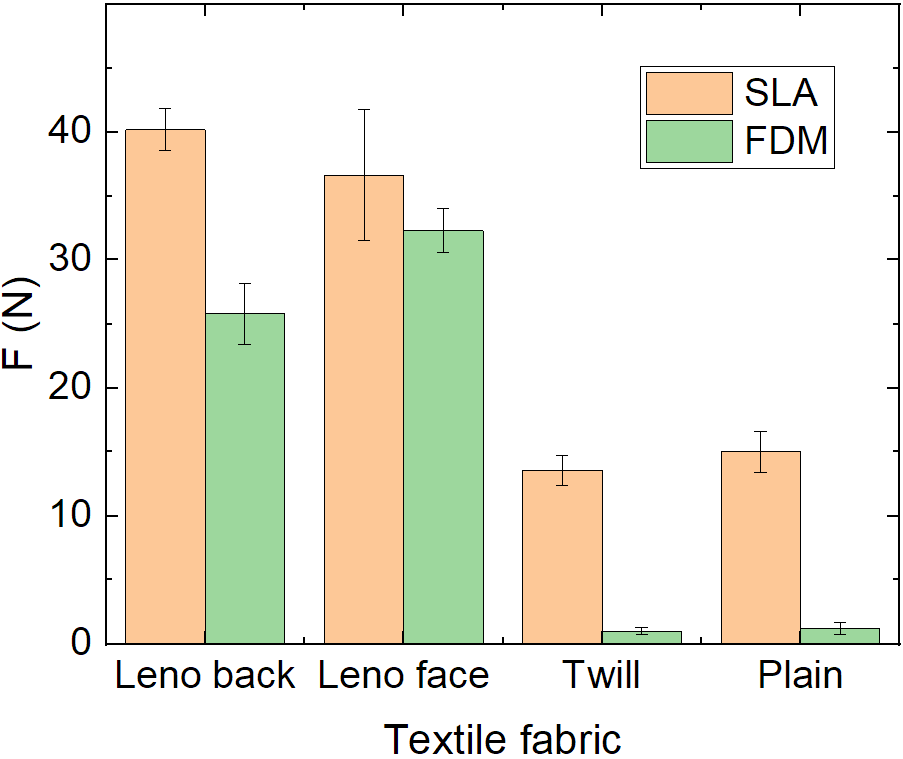

Possibilities to perform 3D printing directly on textile fabrics have been investigated intensively during the last decade. Usually, fused deposition modeling (FDM) printing with often inexpensive 3D printers is applied in these experiments. Several studies revealed the influence of textile fabrics, FDM polymers and printing parameters, indicating that not all combinations of fabrics and printing materials are suitable for this task. Recently, first approaches to use stereolithography (SLA) or PolyJet Modeling (PJM) directly on textile fabrics have been reported. Here, the first comparison of the adhesion forces reached by FDM and SLA printing on different woven fabrics is shown, revealing significantly better adhesion for SLA printing.

References

Oviedo, A. M.; Puente, A.H.; Bernal, C.; Perez, E. Mechanical evaluation of polymeric filaments and their corresponding 3D printed samples. Polymer Testing 2020, 88, 106561. DOI: 10.1016/j.polymertesting.2020.106561.

Szykiedans, K.; Credo, W. Mechanical Properties of FDM and SLA Low-cost 3-D Prints. Proc. Eng. 2016, 136, 257-262.

Zohdi, N.; Yang, R. (C. H.) Material anisotropy in additively manufactured polymers and polymer composites: a review. Polymers 2021, 13(9), 3368.

Dong, J.; Mei, C.T.; Han, J.Q.; Lee, S.Y.; Wu, Q.L. 3D printed poly(lactic acid) composites with grafted cellulose nanofibers: effect of nanofiber and post-fabrication annealing treatment on composite flexural properties. Additive Manufacturing 2019, 28, 621628.

Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587.

Yao, X. H.; Luan, C. C.; Zhang, D. M.; Lan, L. J.; Fu, J. Z. Evaluation of carbon fiber-embedded 3D printed structures for strengthening and structural-health monitoring. Mater. Des. 2017, 114, 424-432.

Richter, C.; Schmülling, S.; Ehrmann, A.; Finsterbusch, K. FDM printing of 3D forms with embedded fibrous materials. Design, Manufacturing and Mechatronics, pp. 961-969 (2015).

Calvo, J.O.; Martin, A.C.; Ferradas, M.I.R.; Morcillo, P.L.F.; Munoz, L.M.; Camo, P.M. Additive manufacturing on textiles with low-cost extrusion devices: Adhesion and deformation properties. Dyna 2019, 64, 8893. DOI 10.6036/8893.

Mpofu, N. S.; Mwasiagi, J. I.; Nkiwane, L. C.; Njuguna, D. Use of regression to study the effect of fabric parameters on the adhesion of 3D printed PLA polymer onto woven fabrics. Fashion and Textiles 2019, 6, 24. DOI 10.1186/s40691-019-0180-6.

Cuk, M., Bizjak, M., Kocevar, T. N. Influence of Simple and Double-Weave Structures on the Adhesive Properties of 3D Printed Fabrics. Polymers 2022, 14(14), 755.

Eutionnat-Diffo, P. A.; Chen, Y.; Guan, J. P.; Cayla, A.; Campagne, C.; Zeng, X. Y.; Nierstraz, V. Stress, strain and deformation of poly-lactic acid filament deposited onto polyethylene terephthalate woven fabric through 3D printing process. Sci. Rep. 2019, 9, 14333. DOI 10.1038/s41598-019-50832-7.

Korger, M.; Bergschneider, J.; Lutz, M.; Mahltig, B.; Finsterbusch, K.; Rabe, M. Possible applications of 3D printing technology on textile substrates. IOP Conference Series: Materials Science and Engineering 2016, 141, 012011.

Grimmelsmann, N.; Kreuziger, M.; Korger, M.; Meissner, H.; Ehrmann, A. Adhesion of 3D printed material on textile substrates. Rapid Prototyping J. 2018, 24(1), 166-170. DOI: 10.1108/RPJ-05-2016-0086.

Demir, M.; Seki, Y. Interfacial adhesion strength between FDM-printed PLA parts and surface-treated cellulosic-woven fabrics. Rapid Prototyping Journal 2023, 29, 1166-1174.

Gorlachova, M.; Mahltig, B. 3D-printing on textiles – an investigation on adhesion properties of the produced composite materials. J. Polym. Res. 2021, 28, 207. DOI: 10.1007/s10965-021-02567-1.

Grothe, T.; Brockhagen, B.; Storck, J.L. Three-dimensional printing resin on different textile substrates using stereolithography: a proof of concept. Journal of Engineered Fibers Fabrics 2020, 15, 1558925020933440.

Kozior, T.; Ehrmann, A. First Proof-of-Principle of PolyJet 3D Printing on Textile Fabrics. Polymers 2023, 15, 3536.

Kozior, T.; Mpofu, N. S.; Fiedler, J.; Ehrmann, A. Influence of textile substrates on the adhesion of PJM-printed MED610 and the surface morphology. Tekstilec 2024, 67, online first. DOI: https://doi.org/10.14502/tekstilec.67.2024080.

Rivera ML, Moukperian M, Ashbrook D, et al. Stretching the bounds of 3D printing with embedded textiles. In: Proceedings of the 2017 CHI conference on human factors in computing systems, Denver, CO, 6–11 May 2017. DOI: 10.1145/3025453.3025460.

Pei, E.; Shen, J.; Watling, J. Direct 3D printing of polymers onto textiles: experimental studies and applications. Rapid Prototyping J. 2015, 21, 556-571. DOI: 10.1108/RPJ-09-2014-0126.

Gruhn, P.; Koske, D.; Storck, J. L.; Ehrmann, A. Three-dimensional printing by vat photopolymerization on textile fabrics: method and mechanical properties of the textile/polymer composites. Textiles 2024, 4, 417-425. DOI: https://doi.org/10.3390/textiles4030024

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Khorolsuren Tuvshinbayar, Nonsikelelo Sheron Mpofu, Thomas Berger, Jan Lukas Storck, Alexander Büsgen, Andrea Ehrmann

This work is licensed under a Creative Commons Attribution 4.0 International License.