The influence of thermal after-treatment on the adhesion of 3D prints on textile fabrics

DOI:

https://doi.org/10.25367/cdatp.2020.1.p104-110Keywords:

3D printing, warp knitted fabrics, ironing, thermal after-treatment, adhesion, nozzle-textile distanceAbstract

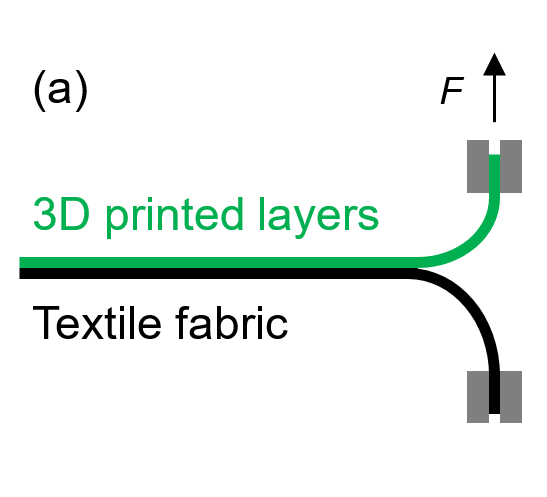

3D printing belongs to the emerging technologies of our time. While it enables producing new structures and makes individualized products affordable, 3D printed objects still suffer from low production speed and often insufficient mechanical properties. Both these problems can be tackled by combining 3D printing with substrates prepared by conventional technologies, e.g. textile fabrics. In this case, the adhesion between both partners is most challenging and defines for which possible applications such composites are suitable. Here, we report on a new approach to increase the adhesion between 3D printed materials and warp knitted fabrics, showing that in some cases a thermal after-treatment, in the simplest case performed by ironing, is able to significantly increase the adhesion between both materials.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Andrea Ehrmann, Daniel Görmer, Jannik Störmer

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.