Key steps in the development of production guidelines for 3D garment simulations

DOI:

https://doi.org/10.25367/cdatp.2024.5.p131-139Keywords:

3D garment simulation; virtual prototyping; production guidelineAbstract

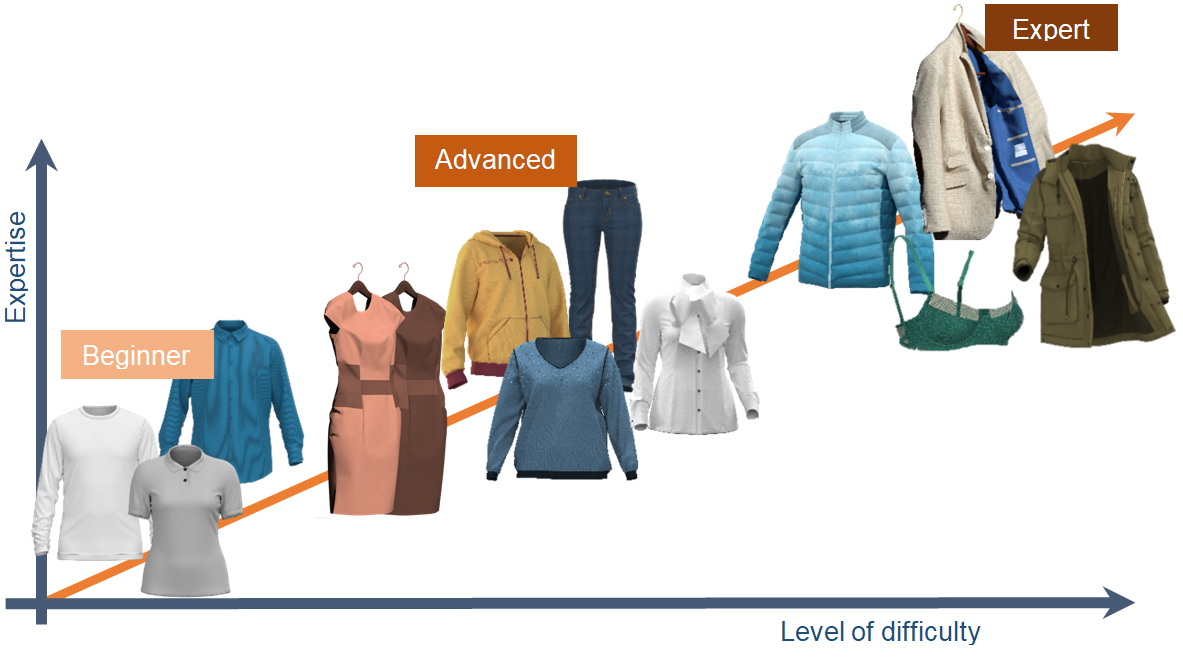

Over the last years 3D garment simulations have improved the workflow of garment production in the clothing industry. While some brands have established themselves as pioneers in this area, planning collections only digitally, other brands are still considering how to start with 3D. 3D clothing simulation enable a clear reduction in product development times from the design idea to the point of sale . To be able to reduce the number of prototypes, it is crucial to create virtual prototypes, that are as close as possible to the final product. To reduce the differences between the physical and virtual garment, production guidelines are needed to establish rules regarding the workmanship of virtual prototypes. A step-by-step description of the processing of virtual garments was made using the simulation system CLO 3D. Different variations of virtual workmanships were shown, with their advantages, disadvantages, optical differences, and applicability. The production guidelines were created for basic garments and then for more challenging products such as winter jackets and bras. It is time consuming to create production guidelines, but the effort is worth it. It enables users and companies to achieve reliable and consistent simulation results.

References

Natalia Toczkowska in Artificial intelligence, News, Virual reality, on 26 October 2023, https://ts2.space/en/digital-only-fashion-virtual-clothing/, 30.10.2023

Daanen, Hein, and Sung-Ae Hong. 2008. “Made-to-measure pattern development based on 3D whole body scans.” International Journal of Clothing Science and Technology 20

(1): 15–25. doi: 10.1108/09556220810843502.

Ernst, Michael. 2009. “CAD/CAM powerful.” Textile Network 4: 20–21.

Sayem, Abu Sadat Muhammad. 2019. “Virtual fashion ID: A reality check.” IFFTI Conference, April 8–11, Manchester Fashion Institute, Manchester (GB).

Morlock, Simone. 2020. “Passform & Schnitt im Wandel—Mit 3D-Technologie in die Zukunft.” TextilPlus 9 (10): 13–15.

Morlock, Simone; Pirch, Christian und Klepser, Anke. 2023. “The virtual fitting process – How precisely does 3D simulation represent physical reality?”. In: Sayem, A.S.M. (Ed.). “Digital Fashion Innovations”.

Zangue, Flora. 2022. Thementag Hohenstein. “Voll im Trend Basisschnitte und Schnittbibliotheken”

Saral Kochar, https://techpacker.com/blog/design/what-is-a-tech-pack/, published on January 12, 2023, 30.10.2023.

Flora Zangue, Christian Pirch, Anke Klepser, Simone Morlock, 2020, Virtual Fit vs. Physical Fit – How Well Does 3D Simulation Represent the Physical Reality, 3DBODY.TECH 2020, 11th Int. Conference and Exhibition on 3D Body Scanning and Processing Technologies, 17-18 Nov. 2020, Online/Virtual, p 3.

Mohammed Didarul Alam, Golam Kabir, Seyedmehdi Mirmohammadsadeghi, A digital twin framework development for apparel manufacturing industry, Decision Analytics Journal 7 (2023) 100252, p.3

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Flora Zangue, Anke Klepser, Simone Morlock, Ailing Chen

This work is licensed under a Creative Commons Attribution 4.0 International License.