A methodology to use digital tools for design and manufacturing of shoe parts as heels

DOI:

https://doi.org/10.25367/cdatp.2025.6.p55-63Abstract

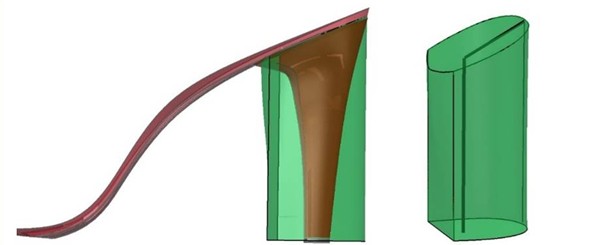

Offering consumers custom-fitted clothing improves customer satisfaction with well-fitted products and waste reduction. Among a wide variety of products, footwear plays a pivotal role in human body health and the high requirements they must fulfill in terms of fit and comfort. Designing footwear products is a complex process that merges the creative part for aesthetic purposes and the technical part for fit and comfort. The spread of using digital tools in footwear production is helping companies to improve their performance and aligns with the sustainability goals required by the footwear industry. This work presents a methodology to design heels as part of a project to use digital tools for footwear products. The first case encompasses the use of the base of a standard heel and creates new heel models. Meanwhile, in the second case is depicted the heel designing based on the surface of the bottom part of the second half-insole. In both cases based on the new shapes, a pattern engineer goes further by creating heel shapes as a complex fantasy. The digital tools part of 3D modeling software presents an easy and efficient way to create these new models. Direct digital manufacturing, like additive manufacturing, presents advantages such as reducing dependence on external manufacturing companies, offering product customization, or waste reduction. They depict the important role of technology as a key driver of the fashion industry

References

Hong. W.H.; Lee, Y.H.; Chen, H.C.; Pei, Y.C.; Wu, C.Y. Influence of Heel Height and Shoe Insert on Comfort Perception and Biomechanical Performance of Young Female Adults During Walking. Foot Ankle Int. 2005, 2(12), 1042-1048. DOI: 10.1177/107110070502601208.

Deselnicu, D.C.; Masilescu, A.M.; Mihai, A.; Purcarea, A.A.; Militaru, G. New Products Development Through Customized Design Based on Customers’ Needs. Part 1: Footwear Comfort Parameters. In 9th International Conference Interdisciplinarity in Engineering 2016, vol. 22, Tirgu-Mures, Rumania, pp. 1043-1050. DOI: 10.1016/j.protcy.2016.01.148.

Jellema, A.H.; Huysmans, T.; Hartholt, K.; Van der Cammen, T.J.M. Shoe design for older adults: Evidence from a systematic review on the elements of optimal footwear. Maturitas 2019, 127, 64-81. DOI: 10.1016/j.maturitas.2019.06.002.

Bondar, O.; Chertenko, L.; Spahiu, T.; Shehi, E. Shoe customization in a mass-production mode. Journal of Engineered Fibers and Fabrics 2024, 19, 15589250241239247. DOI: 10.1177/15589250241239247.

Chertenko, L.; Spahiu, T.; Lypskyi, T.; Almeida, H.; Bondar, O. Developing lasts with removable toe parts for customized footwear. Communications in Development and Assembling of Textile Products – CDATP 2022, 3, 28-41. DOI: 10.25367/cdatp.2022.3.p28-41.

Morris, P.H.; White, J.; Morrison, E.R.; Fisher, K. High heels as supernormal stimuli: How wearing high heels affects judgements of female attractiveness. Journal of Evolution and Human Behavior 2013, 34(3), 176-181. DOI: 10.1016/j.evolhumbehav.2012.11.006.

Ko, D.Y.; Lee, H.K. The Changes of COP and Foot Pressure after One Hour’s Walking Wearing High-heeled and Flat Shoes. J. Phys. Ther. Sci. 2013, 25, 1309-1312. DOI: 10.1589/jpts.25.1309.

Melvin, J.M.A.; Price, C.; Preece, S.; Nester, C.; Howard, D. An investigation into the effects of, and interaction between, heel height and shoe upper stiffness on plantar pressure and comfort. Footwear Science 2019, 11(1), 25-34. DOI: 10.1080/19424280.2018.1555862.

Domjanić, J.; Ujević, D.; Wallner, B.; Seidler, H. Increasing women’s attractiveness: high heels, pains and evolution – a gmm based study. In 8th international textile, clothing & design conference – Magic World of Textiles, 2016, Dubrovnik, Croatia.

Wan, F. K. W., Yick, K. L., & Yu, W. W. M. Validation of a 3D foot scanning system for evaluation of forefoot shape with elevated heels. Measurement: Journal of the International Measurement Confederation 2017, 99, 134-144. DOI: 10.1016/j.measurement.2016.12.005.

Gunal, M.M. Simulation for the Better: The Future in Industry 4.0. In: Gunal, M. (eds) Simulation for Industry 4.0. Springer Series in Advanced Manufacturing. Springer, Cham. 2019; pp. 275-283. DOI: 10.1007/978-3-030-04137-3_16.

Bongomin, O.; Mwasiagi, J.I.; Nganyi, E.O.; Nibikora, I. Simulation metamodeling approach to complex design of garment assembly lines. PLoS One 2020, 15(9), e0239410. DOI: 10.1371/journal.pone.0239410.

Karimi, A.; Razaghi, R.; Sumikura, A. A 3-dimensional finite element model of a newly designed adjustable high-heeled shoe. International Journal of Industrial Ergonomics 2018, 68, 304-310. DOI: 10.1016/j.ergon.2018.09.006.

Sivarao, S.; Sivakumar, S.; Ramesh, S.; Sara Lee, K.Y.; Salleh, M.S.; Ali, M.A.M.; Rao, D.; Kumaran, K.; Pujari, S.; Vatesh, U.K. Finite element analysis of stress distribution on high-heeled shoes. Journal of Engineering Science and Technology 2022, 17(6), 4082-4091.

Yu, J.; Cheung, J.T.M.; Wong, D.W.C.; Cong, Y.; Zhang, M. Biomechanical simulation of high-heeled shoe donning and walking. J. Biomech.. 2013, 46(12), 2067-2074. DOI: 10.1016/j.jbiomech.2013.05.009.

García-Dominguez, A.; Claver, J.; Sebastián, M.A. Optimization Methodology for Additive Manufacturing of Customized Parts by Fused Deposition Modeling (FDM). Application to a Shoe Heel. Polymers 2020, 12(9), 2119. DOI: 10.3390/polym12092119.

Ghimouz, C.; Kene, J.P.; Hof, L.A. On sustainable design and manufacturing for the footwear industry – Towards circular manufacturing. Materials & Design 2023, 233, 112224. DOI: 10.1016/j.matdes.2023.112224.

Milazzo, M.; Spezzaneve, A.; Persichetti, A.; Tomasi, M.; Peselli, V.; Messina, A.; Gambineri, F.; Aringhieri, G.; Roccella, S. Digital and experimental synergies to design high-heeled shoes. The International Journal of Advanced Manufacturing Technology 2020, 109, 385-395. DOI: 10.1007/s00170-020-05675-2.

Lu, H.C.; Chien, W.C. Reshaping the wearing condition of high-heeled shoes by insole design to avoid hallux valgus. International Journal of Industrial Ergonomics 2022, 90, 103299. DOI: 10.1016/j.ergon.2022.103299.

Yung-Hui, L.; Wei-Hsien, H. Effects of shoe inserts and heel height on foot pressure, impact force, and perceived comfort during walking. Appl. Ergon. 2005, 36(3), 355-362. DOI: 10.1016/j.apergo.2004.11.001.

Zhu, A.; Lee, Y.C. Differences in foot shape when wearing wedge-heeled shoes with elevated forefoot height and heel height. Fash. Text. 2023, 10, 28. DOI: 10.1186/s40691-023-00347-7.

Kyratsis, P.; Dimou, E.; Manavis, A.; Bilalis, N. An Inspired from Nature Design Methodology for the Fashion Industry. Applied Mechanics and Materials 2015, 760, 33-38. DOI: 10.4028/www.scientific.net/AMM.760.33.

Spahiu, T.; Chertenko, L.; Almeida, H.; Shehi, E.; Kyratsis, P. Digital tools for design and manufacturing of footwear parts as heels. In 7th International Scientific Conference Contemporary Trends and Innovations in Textile Industry – CT&ITI 2024, pp. 309-319, Belgrade, Serbia. DOI: 10.5937/CT_ITI24034S.

Spahiu,T.; Bogdan, S.; Piperi, E.; Shehi, E.; Agolli, A. Road – map for footwear production:3D last scanning – 3D designing – industrial manufacturing. In 7th International Conference of Textile 2016, 10-11 November, Tirana, Albania.

Chertenko, L.; Booth, B.G. Modelling shape and parameterising style: an approach to the design of high-fashion shoe lasts. Footwear Science 2022, 1(3), 199-218. DOI: 10.1080/19424280.2022.2095041.

Spahiu, T.; Almeida, A.; Manavis, A.; Kyratsis, P. Fashion products through digital manufacturing – A case study with FDM technology. Academic Journal of Manufacturing Engineering 2020, 18(4), 63-72.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Tatjana Spahiu, Yordan Kyosev, Liliia Chertenko, Henrique Almeida, Ermira Shehi

This work is licensed under a Creative Commons Attribution 4.0 International License.